Anping Qianpu Wire Mesh Products Co., Ltd.

Anping Qianpu Wire Mesh Products Co., Ltd. is a metal mesh manufacturing company headquartered in China.

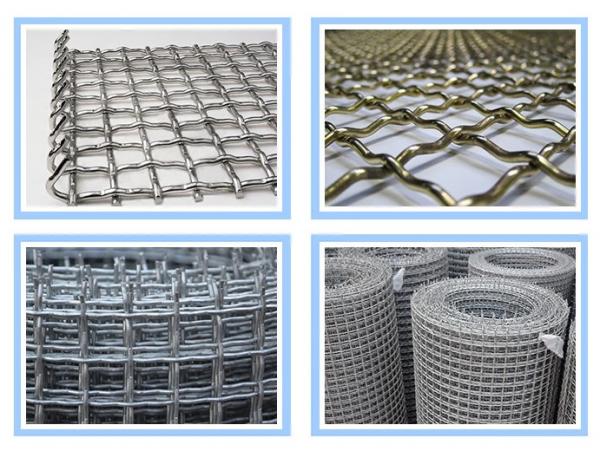

Focuses on the production of various metal mesh products, including

stainless steel mesh, copper mesh, nickel mesh, iron wire mesh,

etc.

The company has advanced production equipment and technical team,

adhering to the concept of high quality, high efficiency and

innovation, and constantly improving product quality and technical

level.

In the past few years, QIANPU has achieved steady growth and good development.

The company not only occupies a certain share in the domestic

market, but also exports to many countries and regions, such as the

United States, Europe, Southeast Asia, etc.

The company's products have been recognized and praised by

customers, and have won a good reputation and word of mouth.

The company's development goal is to become a global leading metal

mesh manufacturer, providing customers with high-quality products

and professional services.

Through continuous innovation and technological upgrading, QIANPU

will continue to maintain its competitive advantage and achieve

sustainable development.

QIANPU is a company specializing in the production and sale of wire mesh.

They mainly produce various types of wire mesh, including stainless

steel wire mesh, galvanized wire mesh, aluminum wire mesh, etc.

These wire meshes are widely used in construction, engineering,

chemical industry, metallurgy, aerospace and other fields.

In addition to wire mesh, the company also provides customized wire

mesh products, which can be customized according to customer needs.

Wire mesh products of different specifications and sizes.

They also provide wire mesh processing services, which can be

processed and produced according to the design drawings provided by

customers to ensure that the products meet customer requirements.

QIANPU is committed to providing high-quality wire mesh products and

excellent services to meet the different needs and requirements of

customers.

Through continuous innovation and optimization of products, the

company enjoys a high reputation and popularity in the wire mesh

industry.

Their products and services have been widely recognized and praised

in domestic and foreign markets.